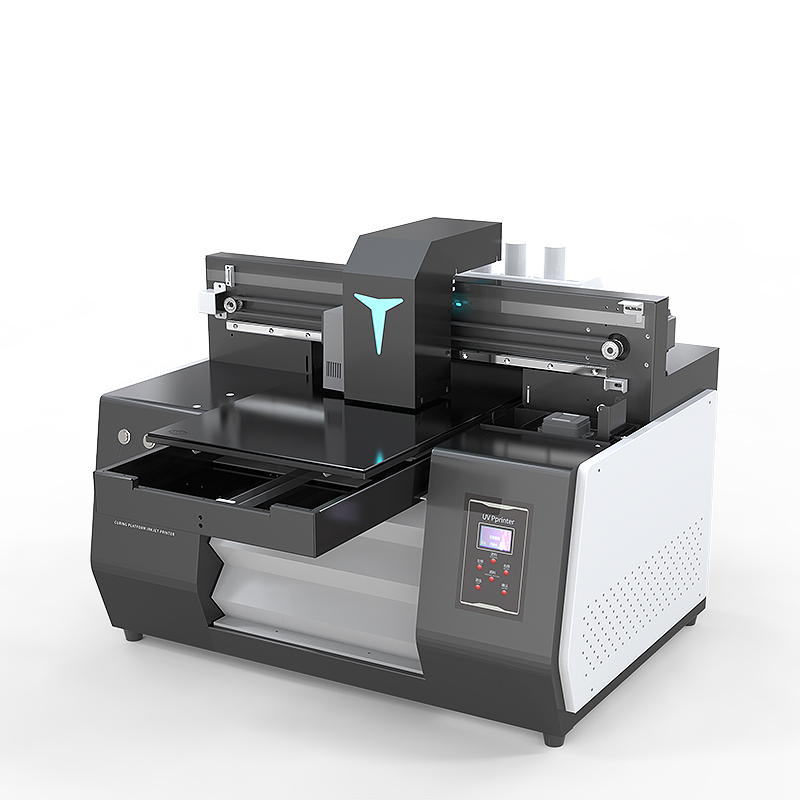

3050 A3 uv Printer

The UV printer utilizes the latest LED cold light source technology without the use of thermal radiation. The surface temperature of the printing material is low instantly without preheating and without any deformation. The power consumption is between 72W and 144W, compared to 3KW for traditional mercury lamps. LED lights have a lifespan of 25,000 hours. The latest generation of Epson nozzles, with intelligent ink dot size allocation, has higher printing accuracy than traditional UV machines. A printing head with 8 rows of nozzles and a multi-channel high-speed printing capability enables you to compete in the market and win more business opportunities. Adopting a high-quality servo, a screw guide system, and low-noise operation, it does not contain mercury and does not produce iron, making it safer and more environmentally friendly. Adopting the water cooling and circulation method can provide a good cooling effect even in hot summer environments with reduced air conditioning.

Immediately spray and dry with a good painting style. In terms of technical challenges such as node control, weak sequential ink printing control, collating strength, and average medium frequency accuracy, reliable technical guarantees have been achieved. Compared to traditional start-up printing, UV printing has bright colours, special priming materials, moving products, and strong market prospects. It's perfect for high-end business card packaging and commercials! Lxrochures, special mediums, desk calendars, personalised needs, special label printing, and other product technology applications in the high-precision cosmetic packaging field are becoming increasingly widespread, showing sustained and stable growth. The new transparent composite material is now being used in plastic packaging due to its storage properties. If these substates cannot be printed using ordinary inks, they must achieve the desired effect through UV technology. Therefore, while natural colors and more UV designsigns are appreciated, the use of UV printing ink is also widespread.

Immediately spray and dry at a high printing speed. In terms of technical challenges such as nozzle control, weak solvent ink printing control, color curing strength, and medium transmission accuracy, reliable technical guarantees have been achieved. Compared to traditional offset printing, UV printing has bright colors, special printing materials, innovative products, and broad market prospects. It is suitable for high-end business card packaging, high-end commercial brochures, special mediums, special desk calendars, special label printing, and other product technology fields. The UV curing process enhances the thickness and performance of the film, reducing raw material consumption and reducing costs.