Several methods for varnishing wine bottles with uv printer

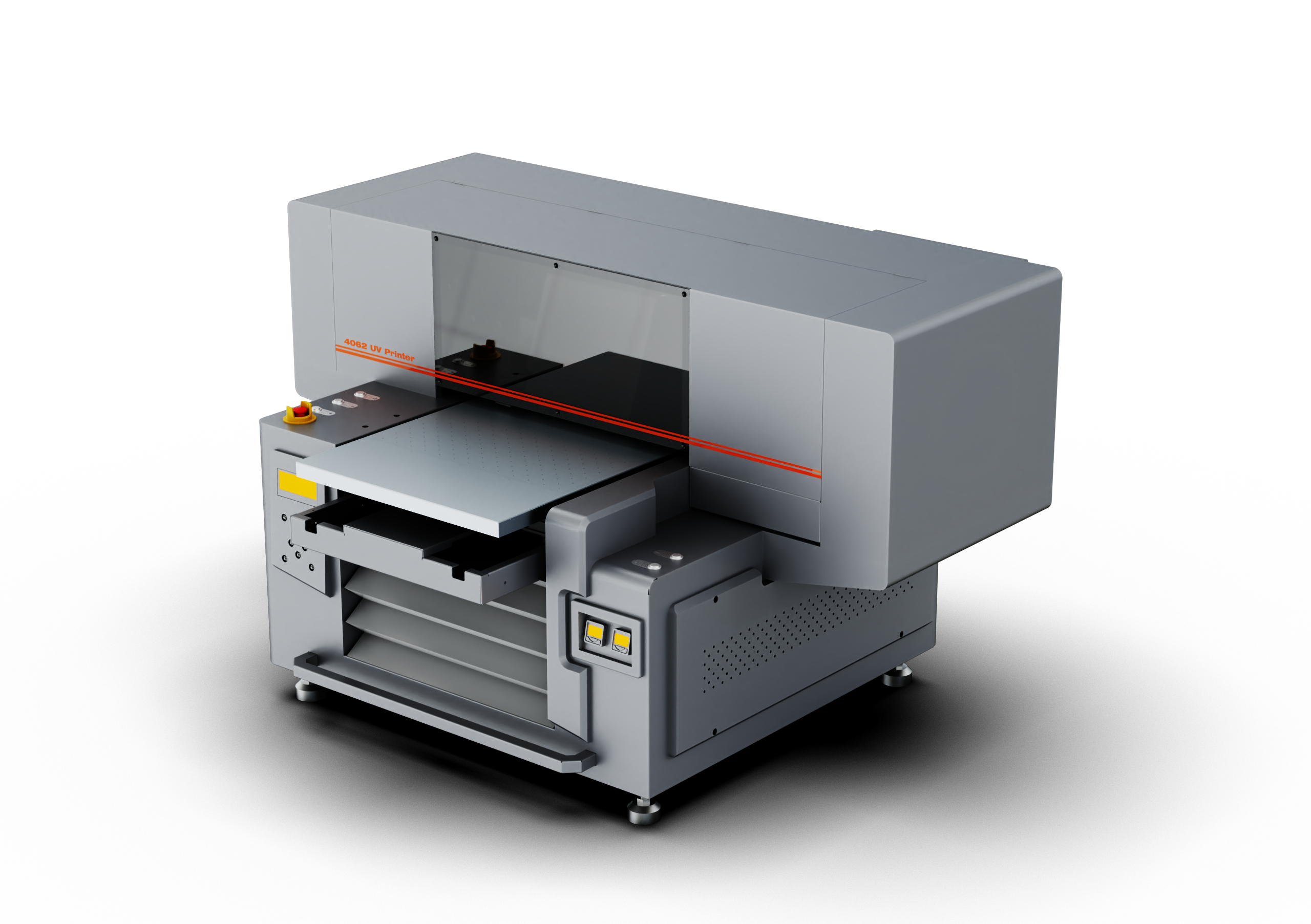

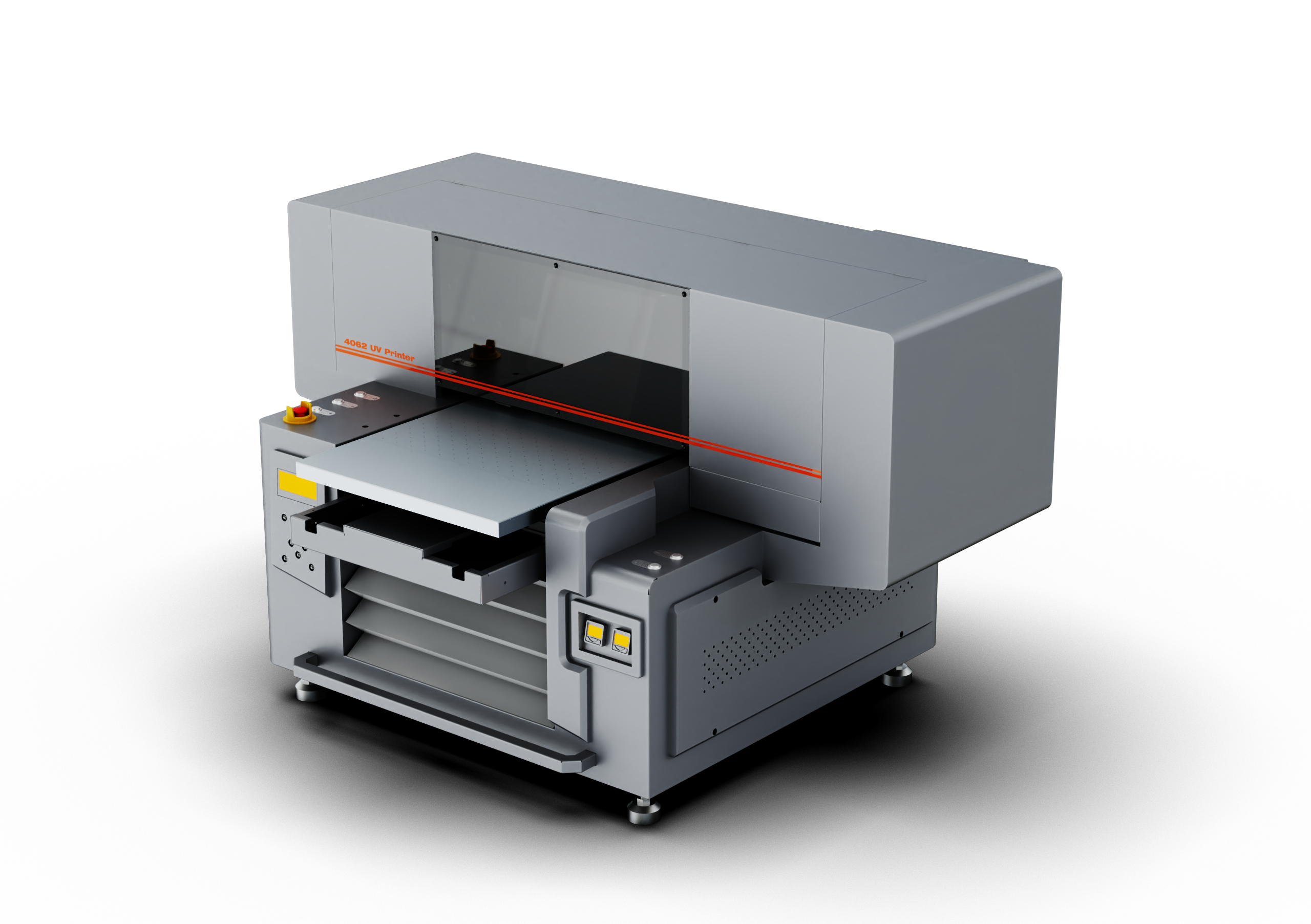

A bottle printer, also known as a bottle inkjet printer, utilizes advanced inkjet technology to overcome the limitations of digital printing, providing users with a cost-effective and excellent experience. This printer meets the user's demand for high-quality printed products and is committed to promoting the popularization of environmentally friendly UV technology, enabling more service providers to enjoy the convenience of UV printing technology. The use of UV varnish enhances the wear resistance, moisture resistance, and protective performance of the patterns, while also serving a decorative purpose.

How is varnishing achieved in popular bottle printers? There are three main methods.

1. Artistic varnishing: This technique is widely used in the decoration of background walls. With the use of special artistic varnishing treatment, the presentation of patterns becomes more three-dimensional, elegant, and artistic.

2. Spot varnishing: During the bottle printing process, varnishing is applied to specific areas of the patterns that require emphasis or have special meanings. This creates a striking contrast between the treated high-gloss parts and the untreated low-gloss parts, creating a captivating visual effect. It is worth mentioning that spot varnishing also includes options for non-gloss or matte varnish, which significantly reduces the glossiness of the print, creating a classic artistic atmosphere.

3. Overall varnishing: This treatment method is suitable for the entire surface of the bottle and is commonly seen on materials like ceramic tiles and phone cases. The main purpose of overall varnishing is to enhance the surface gloss of the entire printed product, giving it a more attractive appearance. When varnishing the entire bottle, it is recommended to add a printhead and ink bag specifically for varnishing.

How much does a custom gift box uv printer cost?

How much does a custom gift box uv printer cost?

Tea box UV printer-120 square meters of printing per hour

Tea box UV printer-120 square meters of printing per hour

Several methods for varnishing wine bottles with uv printer

Several methods for varnishing wine bottles with uv printer

What materials cannot be printed with UV printers?

What materials cannot be printed with UV printers?