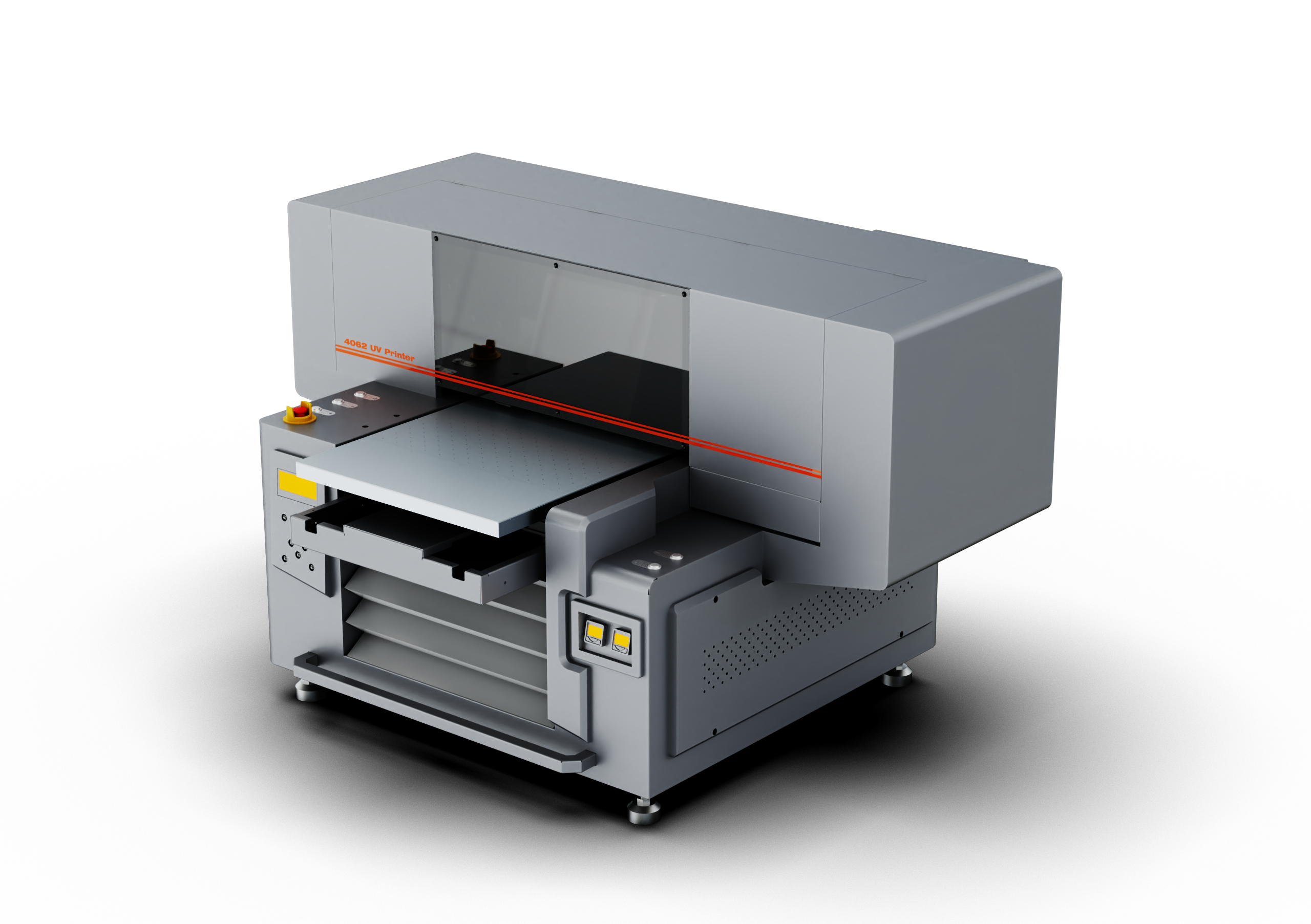

Why more and more people are choosing UV printers?

Why are UV printers increasingly favored by people? This is mainly due to their personalized, large-scale, high-precision, environmentally friendly, and efficient characteristics, which perfectly meet the diverse needs of the modern market. Now, let's delve into the major advantages of UV printers:

1.Meeting personalized printing demands

UV printers can maximize the satisfaction of personalized printing needs. For designers, this means they can fully unleash their creativity and freely modify design drafts on the computer. What you see is what you get, and once the client is satisfied, printing and manufacturing can be done immediately.

2.Unlimited color expression

With UV printers, color choices are no longer limited. There is no need to create screen prints, saving a lot of time. Designing and modifying patterns can be easily done on the computer, and color matching only requires a few clicks of the mouse. This not only eliminates the cost of screen printing but also reduces material and labor expenses.

3.Quick response and shortened production cycle

Traditional printing methods may take several days or even weeks from design and sampling to delivery. However, UV printing technology can complete finished products in just 10 minutes, with no restrictions on production quantity. This small-batch, multi-variety, high-efficiency production process truly achieves quick response and short cycle operations.

4.Environmental-friendly and green production

UV printers do not require water resources, so there is no wastewater generated. Inkjet quantity is precisely controlled by the computer, avoiding waste and reducing water pollution. At the same time, the printing process produces almost no noise, truly realizing a pollution-free green production process.

5.Rich colors and clear, realistic images

Traditional screen printing faces difficulties when dealing with patterns with more than 10 colors, while UV flatbed printing can easily handle it. Whether it is full-color patterns or gradient color printing, it can achieve photo-level effects. This provides a broader space for product design and enhances the overall quality of the product. UV printing creates images that are delicate, rich in layers, and high in clarity, with strong artistic and three-dimensional effects, perfectly presenting photographic and painting-style patterns.

6.Embossed effects and strong three-dimensionality

When using white ink for printing, UV printers can create patterns with embossed effects. This makes the printed patterns lifelike and provides designers with greater creative space. More importantly, the entire printing process is simple and convenient, just like using a home printer. The one-step molding and instant dry features of UV printers far exceed traditional production techniques in terms of production efficiency. It can be foreseen that UV printers have limitless development potential in the future!

How much does a custom gift box uv printer cost?

How much does a custom gift box uv printer cost?

Tea box UV printer-120 square meters of printing per hour

Tea box UV printer-120 square meters of printing per hour

Several methods for varnishing wine bottles with uv printer

Several methods for varnishing wine bottles with uv printer

What materials cannot be printed with UV printers?

What materials cannot be printed with UV printers?