Several major reasons affecting uv flatbed printers

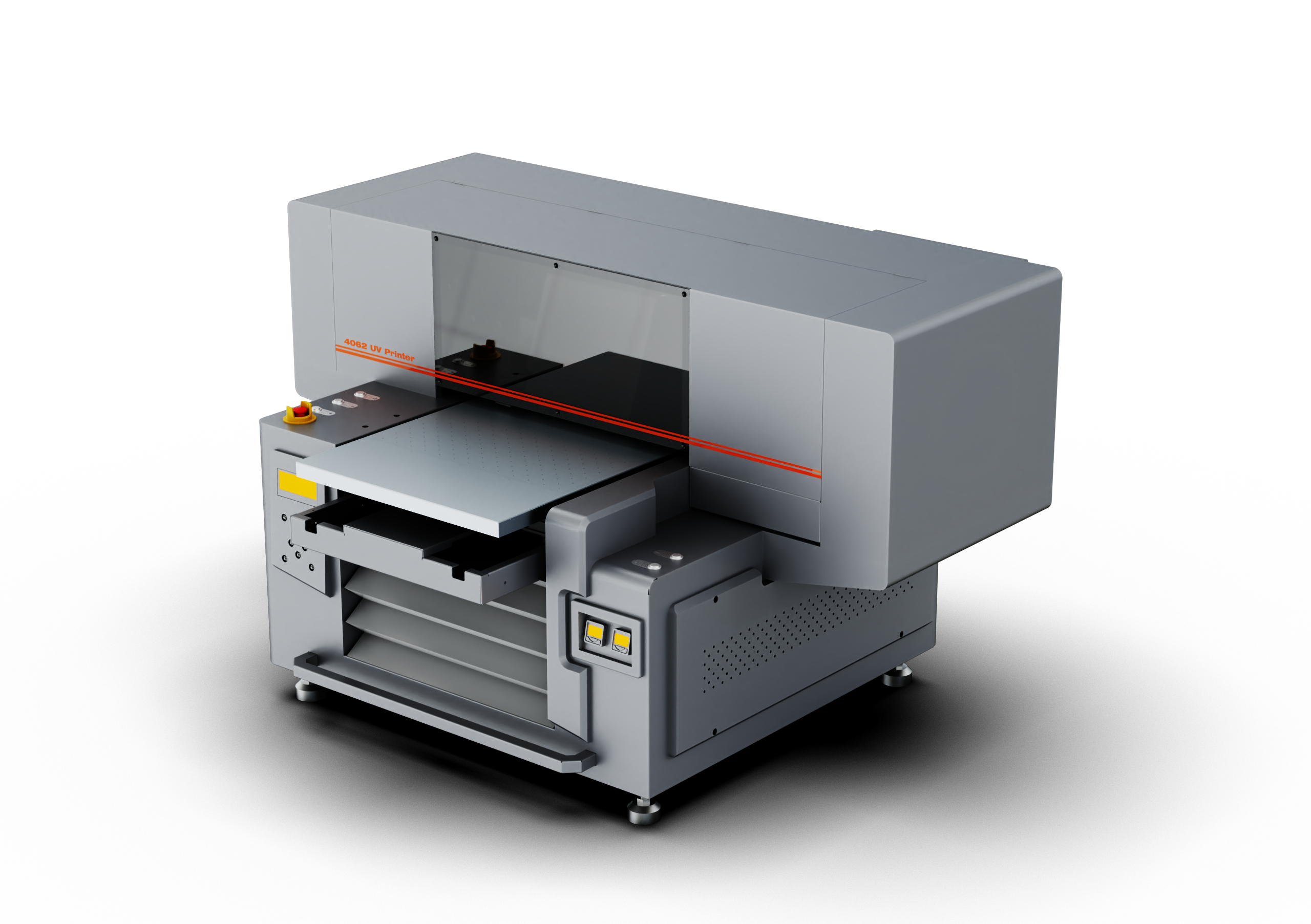

When the printing effect of a UV flatbed printer fails to meet expectations, in addition to potential issues with the equipment itself, the following key factors should be carefully considered:

1.Professional operation: The operation of a UV flatbed printer requires certain skills and experience, which are crucial for the final printing effect. Therefore, it is essential to ensure that operators receive comprehensive and professional training. Only in this way can they master the various functions of the equipment proficiently and produce high-quality prints. When purchasing a UV flatbed printer, consumers should request detailed technical training and equipment maintenance guidance from the manufacturer to ensure accuracy and efficiency in operation.

2.Coating treatment details: For certain materials, appropriate coating treatment is key to improving the printing effect. The uniformity and selection of the coating are crucial. Uneven coating may result in uneven coloring, while using the wrong type of coating may not be compatible with the material and ink. Currently, manual coating and spray coating are common choices, but the specific choice should be based on the material and printing requirements.

3.UV ink quality: The UV ink used in a UV flatbed printer has a direct impact on the printing effect. The quality of the ink and its compatibility with the print head are factors that need to be considered. To ensure the best printing effect, it is recommended to purchase ink directly from the manufacturer or use their recommended products. This is because manufacturers usually work closely with ink suppliers to ensure that the ink is perfectly matched with their equipment, thus providing the best printing effect.

4.Understanding material characteristics: Different printing materials have unique characteristics that can affect the penetration and adhesion of UV ink. Therefore, operators need to have in-depth knowledge of various materials to adjust printing parameters and coating selection in order to achieve the desired printing effect. Especially for materials with high density, such as metal and glass, where ink penetration is difficult, appropriate coating and treatment methods are needed to improve the printing quality.

5.Consideration of image quality: Finally, if there are no issues with the equipment and other factors, the quality of the print image itself needs to be checked. Low pixel or low-resolution images naturally cannot produce clear and detailed printing effects. Therefore, when selecting print images, it is important to ensure that their resolution and clarity meet the requirements in order to achieve satisfactory printing results.

How much does a custom gift box uv printer cost?

How much does a custom gift box uv printer cost?

Tea box UV printer-120 square meters of printing per hour

Tea box UV printer-120 square meters of printing per hour

Several methods for varnishing wine bottles with uv printer

Several methods for varnishing wine bottles with uv printer

What materials cannot be printed with UV printers?

What materials cannot be printed with UV printers?