UV flatbed printing cylinder printer manufacturer

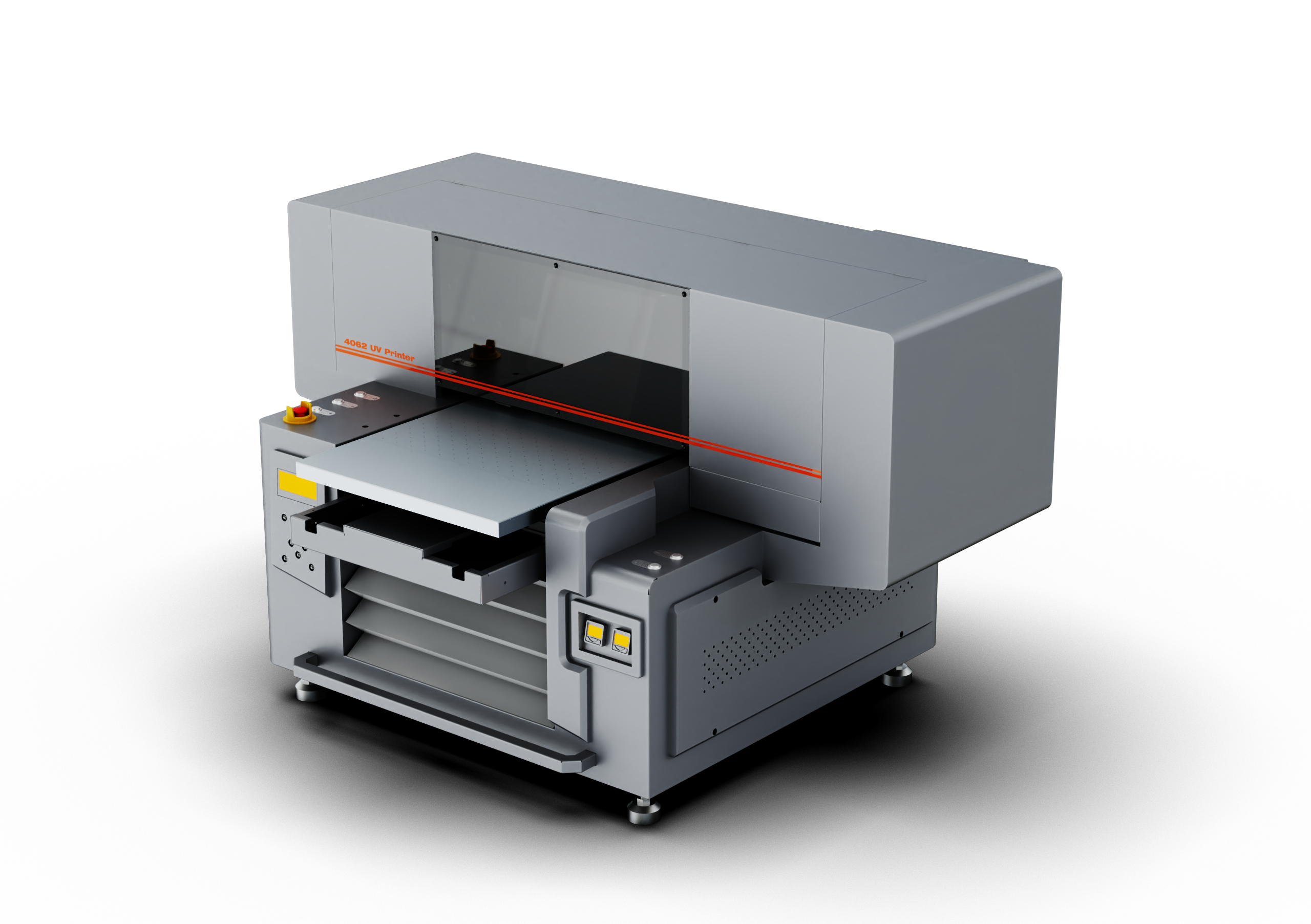

The cylinder, a common shape in our daily lives, is gradually gaining new appeal in various industries as personalized demands continue to grow. What will happen when the cylinder meets a UV flatbed printer? Let's delve into the mystery of UV flatbed printing on cylinders and hear what SONGPUL, a professional printer manufacturer, has to say!

SONGPUL's UV flatbed printer excels in the field of cylinder printing, particularly in printing objects such as wine bottles. It eliminates the need for plate-making by directly printing patterns onto the material's surface, saving time and effort. Before the invention of UV flatbed printers, wine bottle printing was primarily based on stickers or heat transfer technology. However, stickers are prone to damage and are not suitable for long-term preservation, while heat transfer processes are relatively complex and require printing on transfer paper before transferring it onto the bottle.

In contrast, SONGPUL's UV flatbed printer surpasses material limitations. Whether it's simple block patterns, full-color patterns, or gradient patterns, they can be printed without the need for plate-making, screen exposure, or repeated color matching. The printed patterns are more precise. Before printing, SONGPUL applies a UV coating to the material's surface to enhance ink adhesion and ensure long-lasting patterns.

SONGPUL's UV flatbed printer excels on flat surfaces and meets the printing needs of cylinders, enabling personalized customization. Whether it's mass customization of different wine bottle designs or rapid printing of samples, it can meet your needs with high efficiency and low costs, effectively enhancing your product's competitiveness in the market and helping you seize the market faster.

When selecting a UV flatbed printer for cylinders, professionalism, and experience are crucial factors to consider. With over a decade of research and development experience and technical expertise, SONGPUL is a reliable and strong choice for you!

How much does a custom gift box uv printer cost?

How much does a custom gift box uv printer cost?

Tea box UV printer-120 square meters of printing per hour

Tea box UV printer-120 square meters of printing per hour

Several methods for varnishing wine bottles with uv printer

Several methods for varnishing wine bottles with uv printer

What materials cannot be printed with UV printers?

What materials cannot be printed with UV printers?