Winter UV flatbed printer maintenance tips

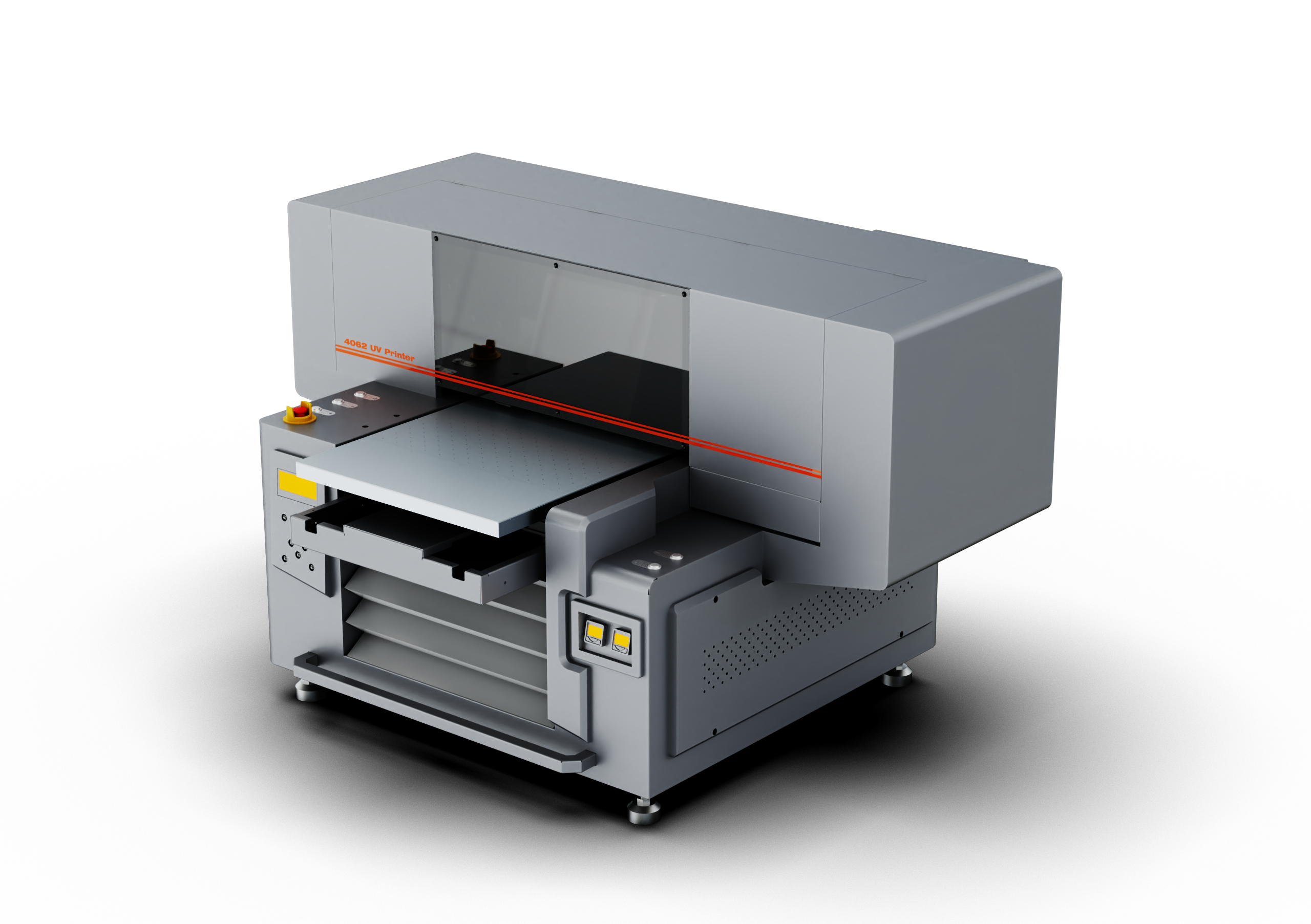

As the temperature drops sharply, the footsteps of winter draw near. Low temperatures can often have adverse effects on machinery and its components, leading to frequent malfunctions. This not only increases additional repair costs but may also seriously affect smooth processing and production. Therefore, for UV flatbed printers, maintenance and care during winter are particularly crucial. Let's follow the steps below to learn about the winter maintenance tips for UV flatbed printers.

1.When starting the machine daily, it is recommended to use a hairdryer to blow briefly on the surface of the UV flatbed printer to remove dust and moisture, ensuring the machine's optimal working condition.

2.To ensure the stable operation of the UV flatbed printer, it should be placed in a suitable working environment. The ideal ambient temperature should be maintained between 10-35°C, with relative humidity controlled within the range of 20-80%. If the equipment is idle for an extended period, it is necessary to extract the ink and thoroughly clean it with specialized cleaning solution to ensure unobstructed print heads.

3.Compared to the humid summer, the air in winter is drier. Therefore, it is important to pay more attention to daily maintenance of the UV flatbed printer in winter, especially by regularly adding a suitable amount of lubricant to reduce friction and wear between machine components.

4.Static electricity can interfere with the normal operation of the UV flatbed printer, causing unstable inkjet and potentially damaging the motherboard and print heads. To effectively prevent static interference, operators should ensure clean hands before operation and strictly follow the operating procedures in the instruction manual. If static interference occurs, operations should be immediately stopped, and the current working environment should be checked for any potential static hazards.

5.At extremely low temperatures, the viscosity of ink increases, which can affect the inkjet performance of the print heads and lead to ink interruptions. Additionally, overly dry air can cause print heads to spatter ink during printing. To ensure proper ink storage conditions and print quality, please ensure that the room temperature is not lower than 25°C and the air humidity is not lower than 50%.

These are the winter maintenance tips for UV flatbed printers. If you encounter any technical issues or confusion during actual usage, please contact our technical support team for professional assistance and guidance.

How much does a custom gift box uv printer cost?

How much does a custom gift box uv printer cost?

Tea box UV printer-120 square meters of printing per hour

Tea box UV printer-120 square meters of printing per hour

Several methods for varnishing wine bottles with uv printer

Several methods for varnishing wine bottles with uv printer

What materials cannot be printed with UV printers?

What materials cannot be printed with UV printers?