How to solve the problem of floating ink on UV flatbed printer!

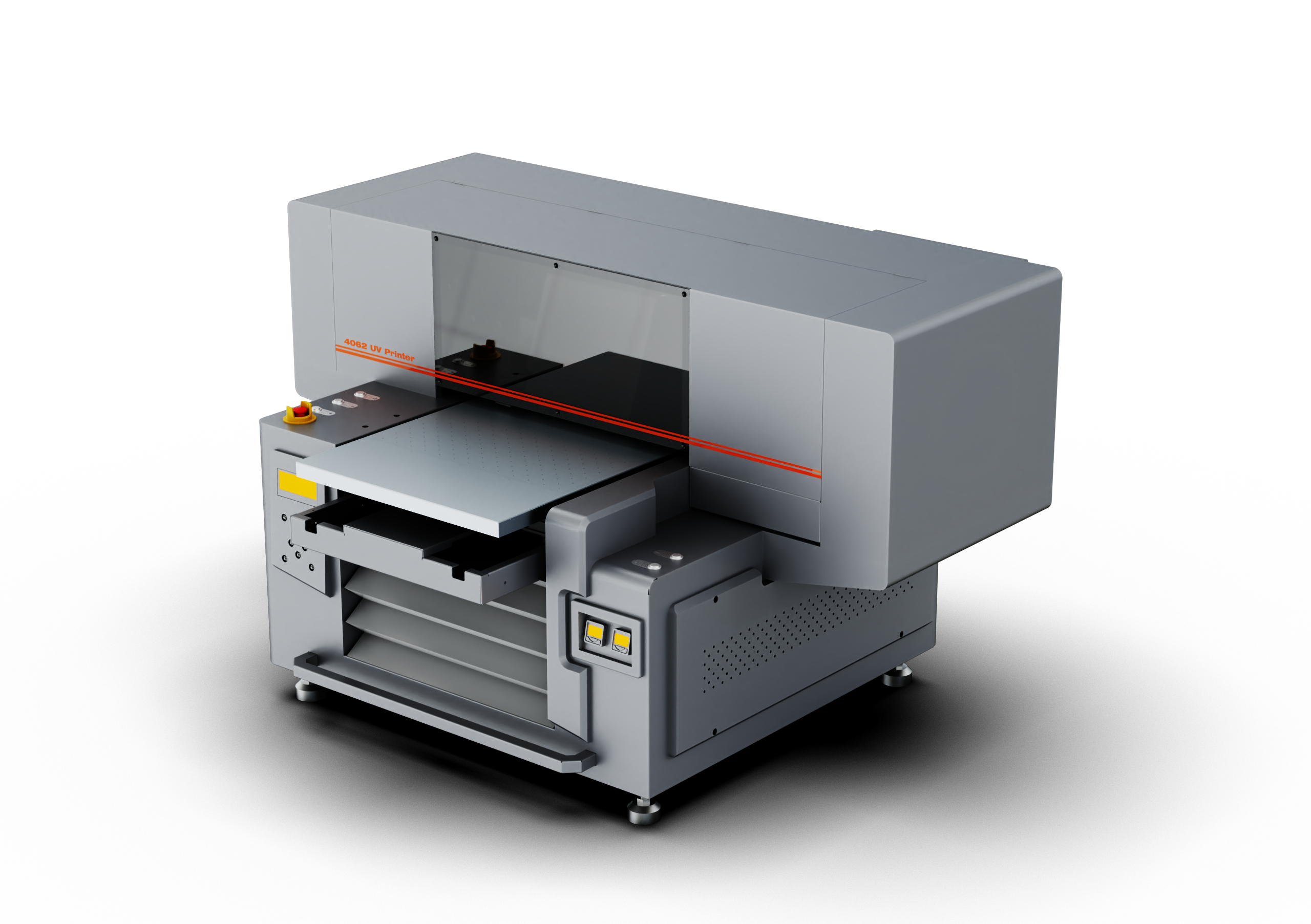

UV printers, as advanced digital printing equipment without the need for plates, have a wide range of applications in various industries, including screen printing, gift processing, signage, decoration, and personalized printing. However, for manufacturers, occasional ink flying is a troublesome issue as it severely affects the printing results and fails to meet customer expectations. Today, SONGPUL will take you through the causes of ink flying in UV flatbed printers and their solutions.

The main causes of ink flying in UV flatbed printers are as follows:

1.Excessive distance between the print head and the product: When the ink droplets ejected by the print head undergo a curved motion rather than falling vertically due to external forces, the landing point of the ink droplets will deviate from the originally determined position. The higher the distance between the print head and the product, the greater the probability of this phenomenon occurring. Therefore, maintaining an appropriate distance between the print head and the product is crucial.

Solution: Adjust the distance between the print head and the material, generally recommended to be controlled within 1.5-2mm to ensure accurate landing of ink droplets.

2.Static electricity and magnetic field interference: During long production processes, static electricity may be generated, resulting in the formation of a magnetic field. When the ink is pressurized, the pressure will decrease due to the effect of the magnetic field, leading to ink flying.

Solution: Add grounding wires and static electricity rods to the equipment to eliminate the influence of static electricity and magnetic fields on ink pressurization.

3.Insufficient print head voltage: Inks vary in type and characteristics, with differences in flexibility, neutrality, and hardness, as well as viscosity. If the ink has poor flowability and the print head voltage is too low, ink flying may occur.

Solution: Increase the correction voltage of the print head appropriately to enhance the ink ejection force and solve the issue of ink flying.

4.Excessive print head voltage: When the indicator light on the print head board displays excessive voltage, lights up in red, or triggers an alarm, it is necessary to reduce the print head voltage to avoid ink flying.

Solution: If it is a modified circuit board, the circuit needs to be adjusted accordingly to reduce the print head voltage. If it is an original circuit board, contact professional technicians for inspection or reset the voltage settings.

5.Print head wire breakage: If the print head is found to be clogged or weak during the printing test, ink flying may occur during the printing process.

Solution: Regularly clean the channels of the print head to ensure unobstructed flow and maintain print quality and results.

6.Electrical control system issues: Improper pulse spacing in the electrical control system that controls the print head ignition can also cause ink flying.

Solution: Contact professional technicians for inspection and adjustment of the electrical control system to ensure its normal operation and prevent ink flying issues. Additionally, regular maintenance and upkeep of the printer are crucial to prolonging its lifespan and improving print quality.

How much does a custom gift box uv printer cost?

How much does a custom gift box uv printer cost?

Tea box UV printer-120 square meters of printing per hour

Tea box UV printer-120 square meters of printing per hour

Several methods for varnishing wine bottles with uv printer

Several methods for varnishing wine bottles with uv printer

What materials cannot be printed with UV printers?

What materials cannot be printed with UV printers?