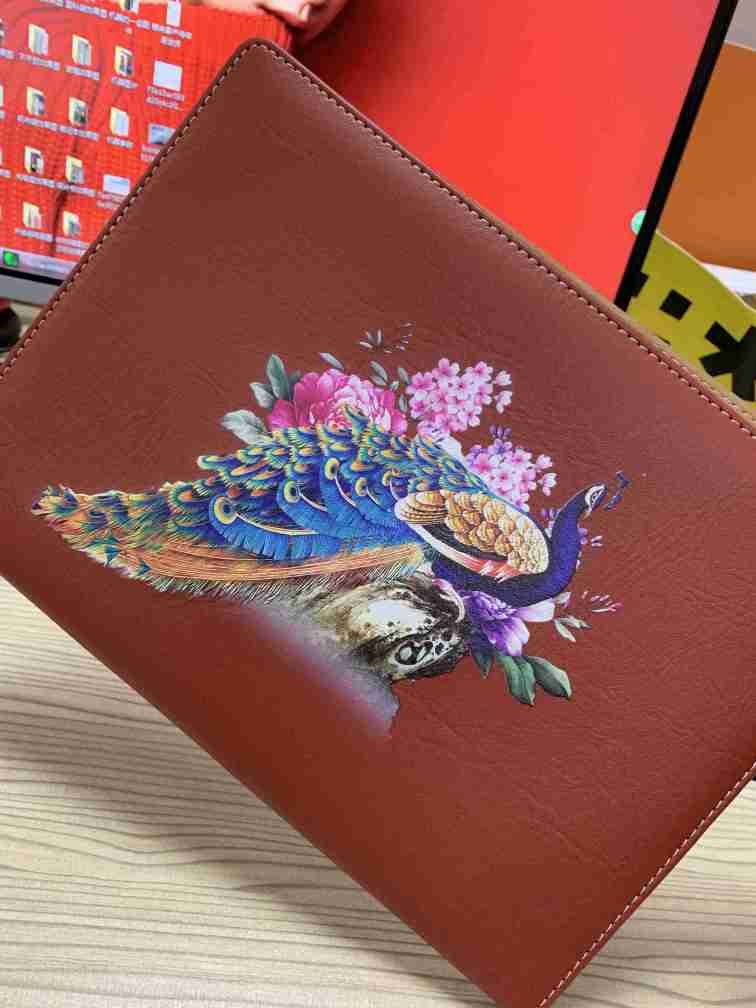

Leather UV flatbed printer, the perfect combination of technology and art!

Leather, as a common material in our daily lives, has seen continuous changes in people's understanding of fashion trends with the progress of society and the evolution of aesthetic concepts. Personalized leather printed products are becoming increasingly popular and sought after. The innovation of inkjet printing technology has brought unprecedented convenience to leather printing. A high-precision and high-speed leather UV flatbed printer can easily meet the increasingly demanding requirements of consumers. So, how does a leather UV flatbed printer achieve this? Let's explore together!

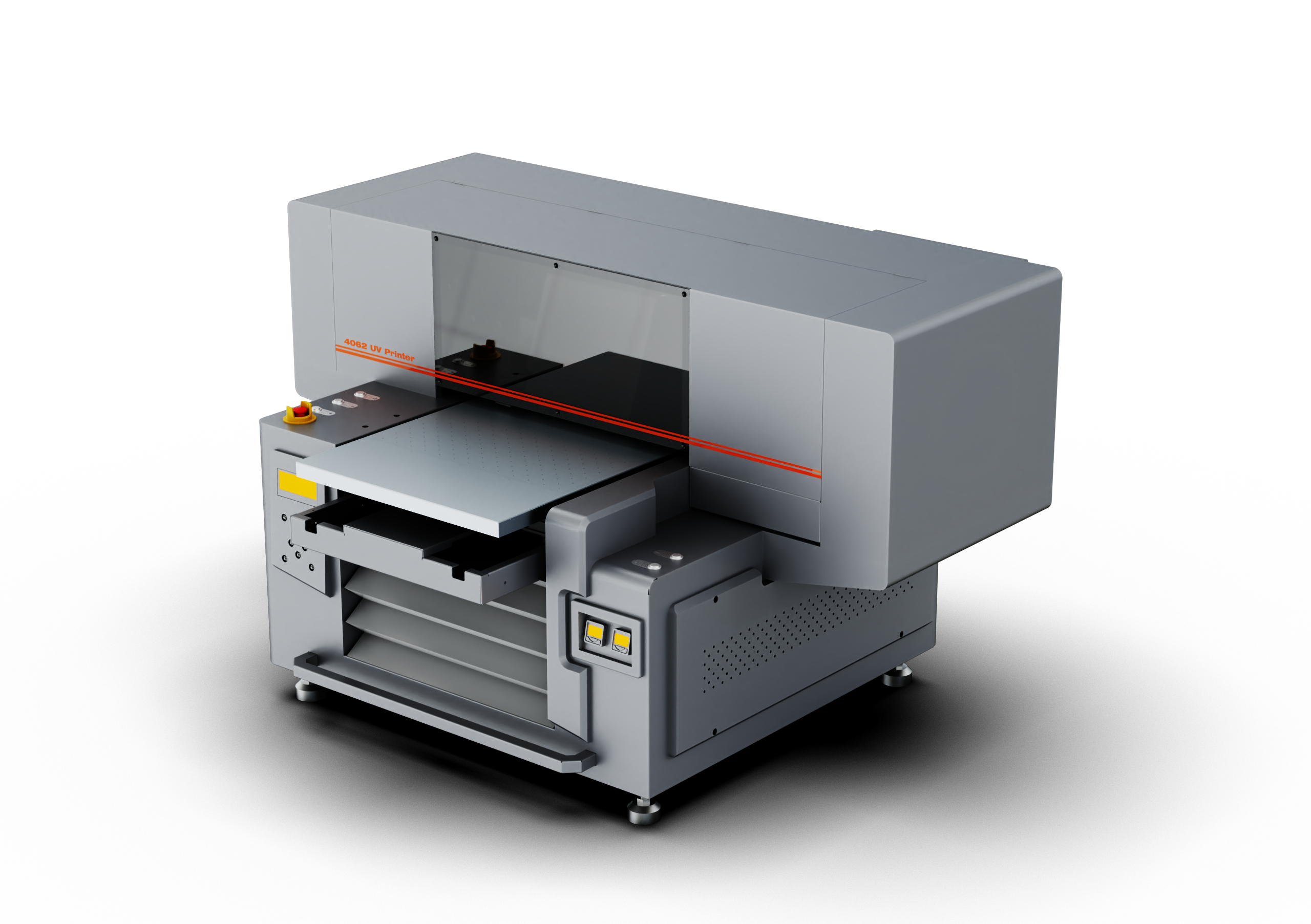

The unique advantages and characteristics of a leather UV flatbed printer are as follows:

1.Personalized customization: Flatbed printers can be customized according to the customer's needs, even for small batch orders. The pattern design is flexible and versatile, capable of meeting various unique creative requirements.

2.Efficient and convenient: Without the need for complicated plate-making processes, the printer can directly produce prints, greatly simplifying the operation process and production steps, thus improving production efficiency.

3.Wide applicability: Various types of leather materials, such as PVC leather, cowhide leather, soft leather, synthetic leather, and PU leather, can all achieve exquisite printing results.

4.Flexible ink selection: Depending on the softness or hardness of the leather, suitable UV inks can be selected for printing. Soft UV inks are suitable for soft leather, while hard UV inks are suitable for hard leather. Some leathers can also be printed with neutral UV inks to ensure printing quality and adhesion.

Leather printing not only eliminates the need for plate-making but also offers fast printing speed, vibrant colors, and clear images, achieving photo-level printing quality. This technology greatly satisfies people's demand for personalized leather products. Additionally, through UV curing technology, printed patterns can firmly adhere to the surface of the leather, maintaining their vibrancy and colorfastness over time.

In the past, the process from product design and sampling to delivery required a long waiting time. However, with SONGPUL's UV flatbed printer technology, the production of finished products can be completed within 2-5 minutes. This not only significantly reduces production costs but also shortens the supply cycle, providing companies with more market opportunities.

With the popularity and application of leather UV flatbed printers, more and more personalized leather products have entered people's daily lives. They not only serve basic practical functions but also become important vehicles for showcasing individuality and fashion taste. If you have any questions about UV flatbed printers or would like to learn more information, please feel free to consult SONGPUL. We will be happy to answer your inquiries!

How much does a custom gift box uv printer cost?

How much does a custom gift box uv printer cost?

Tea box UV printer-120 square meters of printing per hour

Tea box UV printer-120 square meters of printing per hour

Several methods for varnishing wine bottles with uv printer

Several methods for varnishing wine bottles with uv printer

What materials cannot be printed with UV printers?

What materials cannot be printed with UV printers?