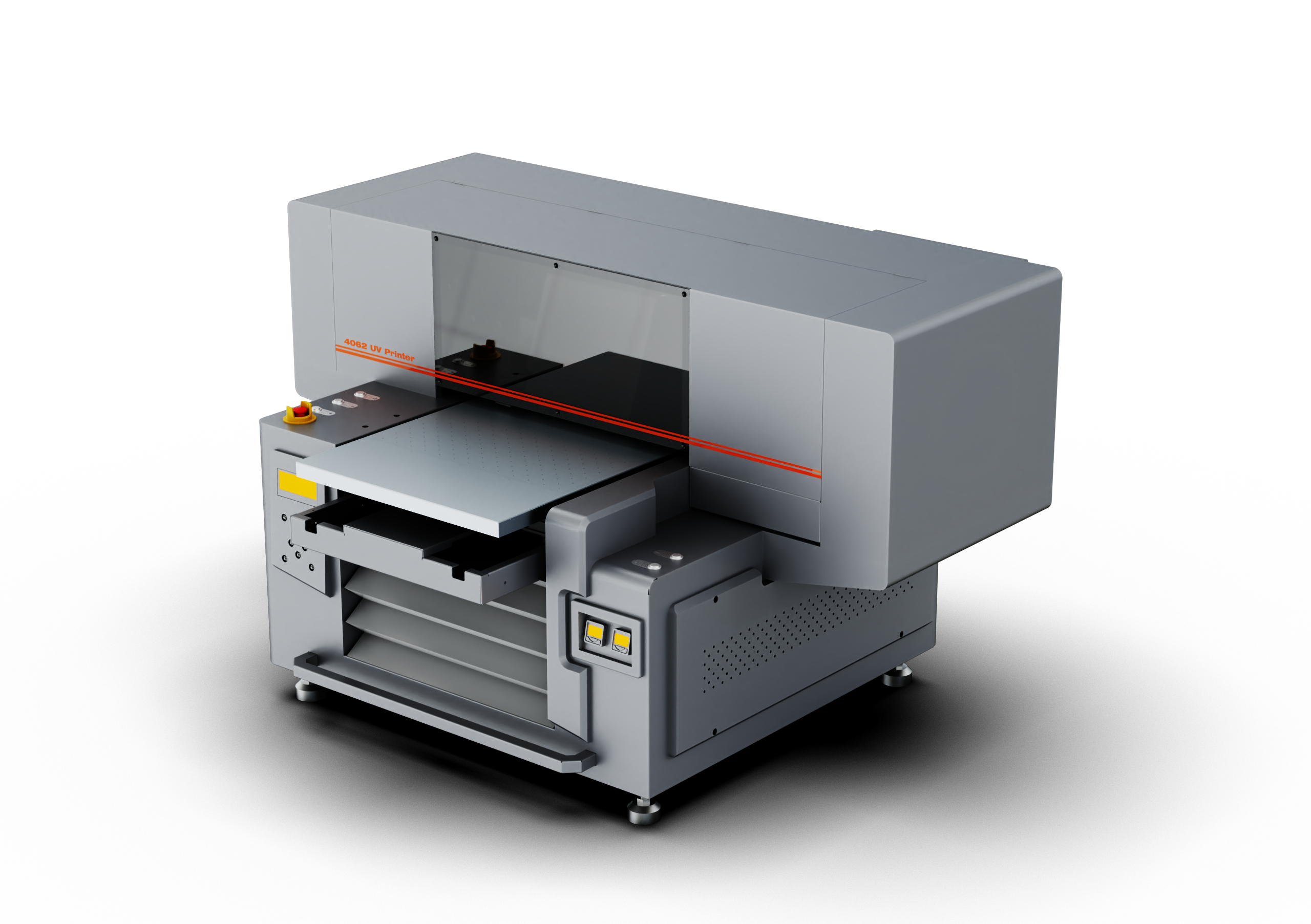

New breakthrough in toy uv flatbed printer

Children's preferences for toys are always unpredictable, and the novelty quickly fades away. In the fierce market competition, toy manufacturers must constantly innovate to stay ahead. With the development of UV flatbed printing technology, printing toys using UV flatbed printers has become a new trend. This technology provides a powerful weapon for toy manufacturers to quickly seize the market.

UV flatbed printers not only perform well on soft materials but also achieve high-quality printing on hard media with a thickness of several centimeters. It is mainly aimed at the industrial digital printing market and can perform digital printing on rigid materials. Its unique production method and characteristics bring great value for surface painting and decoration on toys.

SONGPUL's toy UV flatbed printers have significant advantages in printing toys:

1.No need for plate making, fast and cost-effective printing process, compatible with various output software and file formats.

2.Rapid curing, no volatile organic compounds, green and environmentally friendly production process.

3.One-time printing, instant output, meeting the needs of rapid sampling and finished products.

4.Transfer images directly from the computer to the machine, printing them on the medium, and realistically reproducing decorative artwork.

5.Easy computer operation, no need for professional personnel, and broad upgrade potential.

This printer is suitable for toys made of various materials such as metal, glass, ceramics, acrylic, crystal, PVC products, aluminum plates, stainless steel, plastic, leather, and more. With one-time printing and instant output, it not only meets the needs for rapid sampling and finished products but also has low costs.

The innovative toy UV flatbed printer brought by SONGPUL, if cleverly applied in toy design, will undoubtedly bring new development opportunities to the toy market. We look forward to the widespread application and profound influence of this technology in the toy industry.

How much does a custom gift box uv printer cost?

How much does a custom gift box uv printer cost?

Tea box UV printer-120 square meters of printing per hour

Tea box UV printer-120 square meters of printing per hour

Several methods for varnishing wine bottles with uv printer

Several methods for varnishing wine bottles with uv printer

What materials cannot be printed with UV printers?

What materials cannot be printed with UV printers?